- Home

- /

- Manufacturing plant

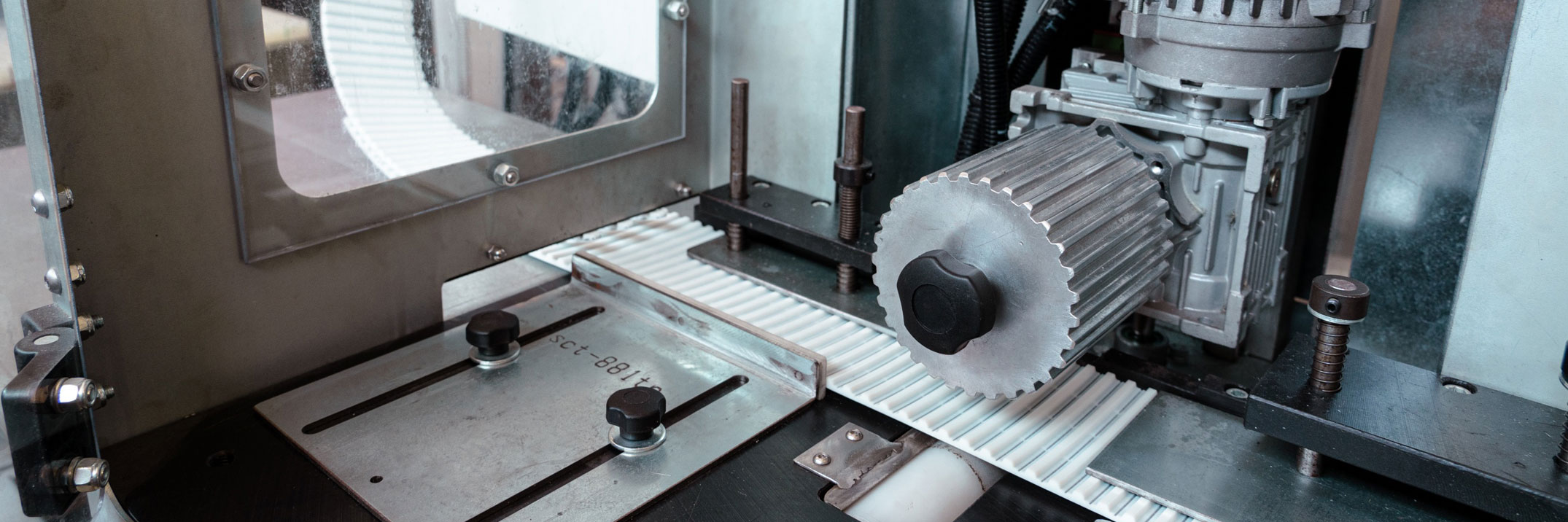

MANUFACTURING PLANT

In our production plant we realize conveyor belts, transport and transmission belts according to the customized dimension given by user, prepared with state of the art machineries and equipment:

- Hydraulic presses for welding from 300 to 3000 mm

- Electric presses for assembly at customers’ plant

- PLC grinding machine for belt preparation

- PLC edges grinding machine for belt’s top coating preparation

- 2 surface grinding lines to rectify and obtain a perfect thickness along the entire surface of belt top coating

- Pantograph to cut, drill customized details and realize, milling, countersinking, buttonhole on belt top coating

- High frequency machine

- Timing belt department

- Sponge rubber and belt and coating processing department

Our commercial and technical staff are able to provide

- Quick pre- and post-sale technical assistance

- Technical support for product choice

- Management of scheduled and emergency orders

- Welding and joints directly at the customer’s site

REQUEST A QUOTE OR ADDITIONAL INFORMATION

Our technicians will be glad to propose you the best solution. Please send us your enquiry filling in the following fields

PRODUCTS AND SERVICES

Supply, processing and installation of conveyor belts, power transmission and carrier belts

Conveyor Belts

Wide range of carrier and conveyors belts for processing in the light materials handling industry.

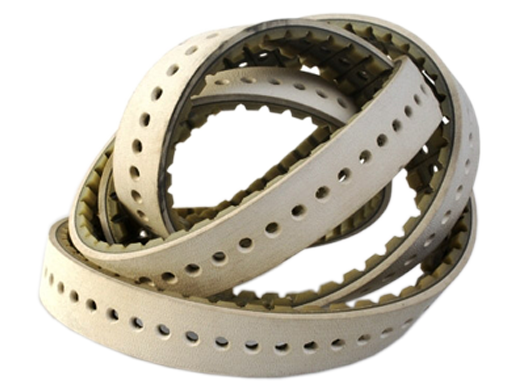

Power Transmission - Timing Belts

Wide range of flat power transmission belts and toothed belts.

Sponge Rubber

Conveyor belts with sponge rubber coating and cylinders in different types, quality, density

Special Processing

Coatings on conveyor and power belts with a large choice of different materials

WE PROVIDE CONSULTING,

AFTER SALES SERVICE, ASSISTANCE

AND INSTALLATION SERVICE AT PLANT

Send us your request

Tel: 0574 632263 – Fax: 0574 632467 – P.I. e C.F. 01867830976 info@toscananastri.com